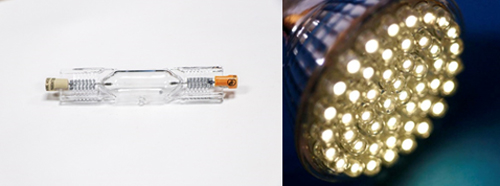

LED光固化优势

随着人们对 LED 技术的兴趣日益浓厚,它正成为传统广谱光固化的理想替代品,而后者几十年来一直是行业标准。与汞弧灯相比,LED 具有许多优势。LED 固化温度更低,可实现更好的热管理,并提供非常稳定的强度,从而实现更一致的过程控制。LED光固化系统可立即启动,提供即时光能,预期 LED 使用寿命超过 20,000 小时,与传统灯系统相比,可显著减少停机时间并降低灯更换成本。与传统的广谱UV固化相比,LED 固化技术具有许多优势,例如更低的运营成本和“绿色”属性,可消除汞和臭氧安全风险。

气温较低

LED 系统的工作温度比传统的广谱灯低。较冷的固化可实现更好的热管理,其窄波长光谱发射可最大限度地减少热量上升。由于某些基材对较高温度敏感,因此完全光固化固化材料而不损坏基材可能需要在较低强度水平的广谱灯下多次通过。通过切换到较冷的 LED 装置,可以省去这些额外的步骤。

LED 系统温度较低的另一个优点是它们不需要相同水平的热量提取(排气),从而省去了昂贵的安装和运行成本。

更长寿命

LED 固化源的另一个好处是使用寿命更长。尽管 LED 的强度输出也会随着时间的推移而降低,但典型的广谱点固化灯在强度输出水平降至初始水平的 50% 左右之前可能可持续使用约 2,000 小时。相反,LED 固化装置通常可以在更长的时间内提供超过其原始强度输出的 50%。

更统一的治疗方法

LED 可在固化区域内提供更均匀的光线分布,从而获得更一致的效果。

立即开启

LED 可即时通电,无需任何预热时间。这样可以立即开始生产,从而提高产量。

更节能、更环保

LED 系统比汞弧固化灯更节能,更环保。LED 以较低电压运行,无需预热,从而降低了电力成本。它们也不像传统的汞弧灯那样被列为电气危险。

Dymax LED光固化系统由于其独特的设计,可实现均匀的频率和强度输出,从而实现一致的固化,从而有助于更好地控制工艺并提高生产能力。其他优势包括:

- 紧凑型设备可减少光固化系统的尺寸和成本

- 灵活的光传输配置

- 非常稳定的灯光强度可实现一致的过程控制

- 与传统固化系统相比,使用寿命长,无需更换灯泡,降低了维护成本

- 高电气效率和即时开/关功能可降低运营成本并提高自动装配速度

获取我们的综合指南了解有关 Dymax LED光固化系统的更多信息。