观察其分配。观察其治愈。观察其解决方案。

关于光固化胶粘剂和涂料最常见的两个问题是:

1. 我如何知道我已经在适当的区域分配了足够的材料?

2. 如何知道材料何时完全固化?

眼见为实。

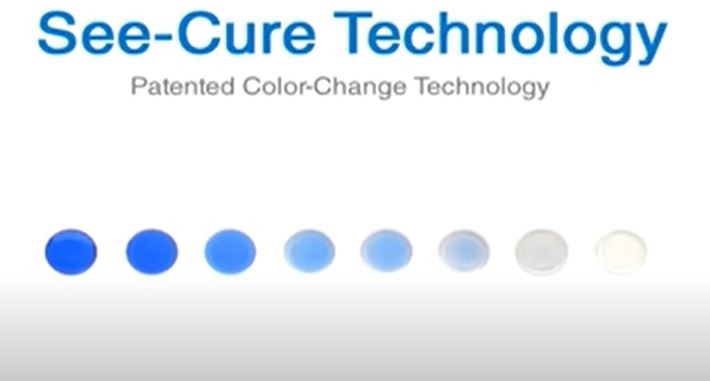

See-Cure 是 Dymax 开发的一项专利变色技术,可帮助制造商查看光固化材料 (LCM) 是否已得到适当分配和固化。

该技术通过有意将 See-Cure 配方产品的颜色转变为无色,或在某些情况下转变为粉红色,来指示完全固化。颜色转变不是紫外线照射漂白的效果,而是与材料中的光引发剂直接相关。See-Cure 确保在装配过程中内置可见的安全因素。这种内置的视觉固化验证使操作员或简单的自动光学检测系统可以轻松确认固化,而无需额外的专用设备。该技术不会影响光固化材料的 RoHS 合规性,并为 Dymax 提供类似的生物相容性特性 MD®医疗器械胶粘剂。

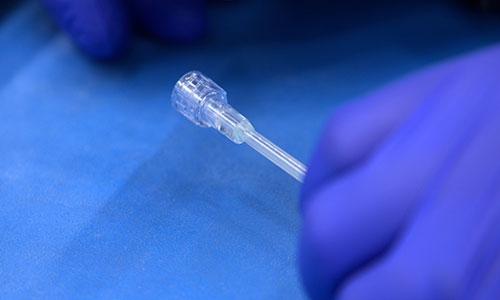

看到它分配了!

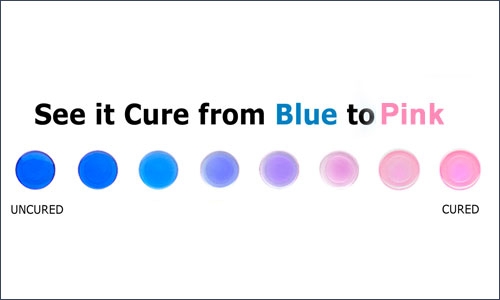

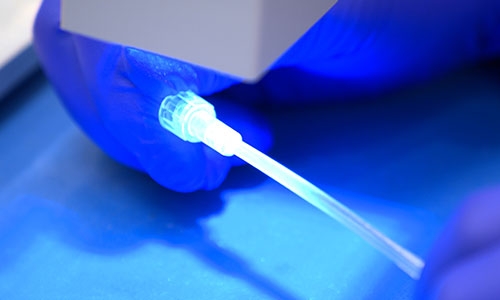

Dymax 粘合剂和掩膜采用 See-Cure 技术配制的粘合剂在未固化状态下呈亮蓝色或紫色。当将粘合剂涂到基材表面、深孔中或两层材料之间时,用户可以轻松确认材料位置。这些颜色不会永久染色或影响其接触的组件表面的生物相容性。由于这些鲜艳的颜色非常显眼,因此可以在固化之前将简单的视觉系统纳入组装流程,以轻松识别材料覆盖范围和轮廓。

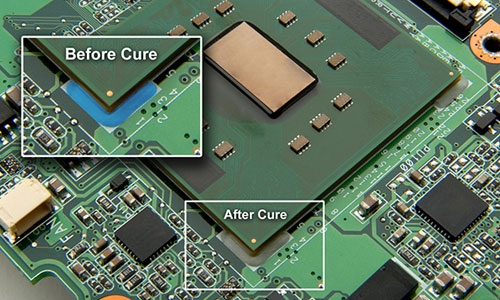

看它治愈!

在光固化过程,采用 See-Cure 技术配制的 LCM 的初始鲜艳颜色会变成无色或粉红色。这种变色技术提供了明显的视觉确认,即材料已接收到足够的能量以达到完全固化,并且粘合线牢固。

查看解决方案!

为了绝对确保视觉清晰度和完全固化之间的关系,Dymax 特意采用 See-Cure 技术配制LCM ,使颜色变化比实际胶粘剂固化固化慢 10-20%。由于光固化材料通常在几分之一秒内固化,因此完成从蓝色到无色或粉红色的颜色转变所需的额外时间通常可以忽略不计。这种程序化的延迟支持良好的工程和制造实践,这些实践要求粘接过程必须具有合理的“过度固化”时间作为安全系数。

为了验证 See-Cure 技术是否始终可以作为完全固化的可靠指标,Dymax 对各种光固化胶粘剂进行了广泛的测试。为了说明 See-Cure 技术的概念,在固化周期内测量产品硬度以确定完全固化点。将这些测量值与相同时间间隔下的粘合剂颜色强度测量值绘制成图。下图描绘了胶粘剂固化进程与粘合剂中 See-Cure 技术颜色减弱之间的典型关系。通过绘制的测量结果验证,胶粘剂固化后,最终颜色从蓝色变为无色。

亲自体验 See-Cure 技术!请联系我们的应用工程团队,获取有关可用产品的更多信息。