使用紫外线光固化系统时限制曝光的方法

紫外线 (UV) 是一种电磁能人类看不见。紫外线比可见光低,因此不会触发眼睛的自然防御机制,例如明亮可见光引起的瞳孔扩张。因此,务必使用个人防护设备和强度测量设备,并且不要禁用为UV光源设计的任何安全控制措施,以限制暴露。

许多人经常误以为这些系统发出的强光是有害的,但他们看到的是无害的可见光。虽然所有紫外线在使用不当的情况下都有可能伤害员工,但短波紫外线 (UV-C) 能量对使用这些光源的人构成的最大风险。工业光固化胶粘剂市场中销售的大多数紫外线源都包含更安全的 UV-A 能量。在使用紫外线源之前,检查其规格至关重要。

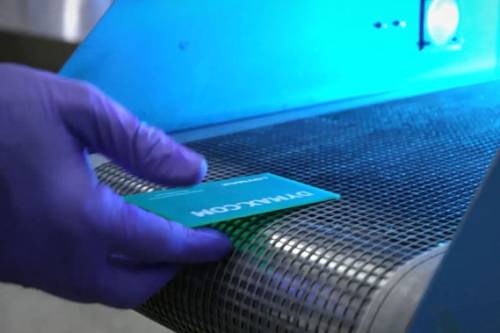

操作员将印刷电路板放入紫外线光固化传送带中。

在工业环境中,用户常常误解紫外线照射,但正是在这些环境中,制造商对工人的健康和安全拥有最重要的控制权。

解决杂散光问题

紫外线光固化系统通常内置有安全或工程控制。这些控制,如屏蔽、安全联锁、直观设计和吸光塑料,使操作员可以在不暴露于有害紫外线的情况下使用它们。

光固化系统,例如 Dymax 2000-ECE 泛光固化灯,可以在其各部分之间发出杂散的可见光。这种光可能会引起用户的担忧,因为他们认为可见光中含有 UV-A。为了消除这些担忧,制造商可以使用辐射计。该设备可以测量光强度,并可以显示员工在操作UV固化设备时接触到的紫外线量。在设备开启时,将辐射计的传感器放在人裸露的皮肤附近,然后将其与人在晴天户外接受的照射量进行比较,将显示个人受到的太阳照射量更大。

一个辐射计还可以帮助证明固化装置发出的可见波长杂散光量不包含 UV-A。UV-A 不会从大多数表面反射,因此当它照射到表面时会被吸收并转化为热量。2000-ECE面光源固化灯是二向色的,可将 UV-A 能量直接向下反射到工作表面。如果系统采用 ZIP™ 快门,辐射计可以验证它是否完全关闭,从而不会有杂散光逸出。当窗帘关闭时,它应该测量到零紫外线强度。将辐射计与被测紫外线波长相匹配至关重要。

辐射计可以测量固化装置发出的杂散光量。

使用个人防护设备

保护操作员免受光照的其他方法包括使用防护罩、护目镜、眼镜、面罩、手套和长袖。

手动(3面)和电动光盾泛光固化灯可为用户提供 360° 眼睛和皮肤保护,防止紫外线和可见光,同时清晰可见固化部件。但是,仍需佩戴防紫外线安全眼镜或护目镜,以防杂散光或意外照射。

使用遮光罩保护用户免受光线照射。

任何能看见光的人都应该佩戴紫外线护眼使用任何广谱或 LED 固化系统时,因为这两种系统都会产生 UV-A 波长范围内的光。Dymax 提供符合 ANSI 87.1 标准的护眼解决方案,具有最大 UV-A 吸收率,可降低高强度光带来的亮度和刺激。

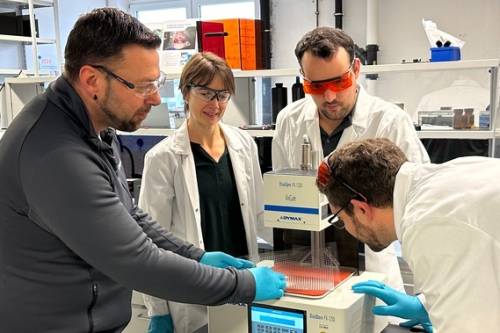

员工在使用UV设备时必须佩戴紫外线护目镜。

戴手套保护双手免受紫外线照射是另一种选择。在 Dymax,我们使用一次性无粉丁腈手套。我们不推荐特定品牌或类型的手套,但不透明或防紫外线的手套是理想的选择。

另一种有效的 PPE 解决方案是穿长袖实验服,以保护皮肤免受有害紫外线的伤害。

戴上手套和实验服来保护自己免受紫外线照射。

也可以穿上实验室工作服和防紫外线手套,使用定制夹具将两个组件固定在固化装置下方。使用适当的 PPE 和夹具可使手和手臂远离杂散光,从安全和一致性的角度来看是有效的。

只要配备正确的个人防护设备、使用辐射计并接受适当的培训,工业UV光源就安全且易于使用。教导员工如何保护自己免受紫外线照射并培训他们在这些UV系统周围安全工作,将最大限度地降低任何潜在伤害风险。