辐射计有助于确保一致的性能、防止固化错误并延长紫外线和 LED光固化应用中的设备寿命。

辐射计在维持光固化系统的质量和一致性方面发挥着至关重要的作用。以下是它们对用户必不可少的原因:

确保一致的固化性能

随着时间的推移,紫外线和 LED 灯泡会退化,导致强度降低,从而影响固化过程。 辐射计允许用户监控输出并确保光源在所需参数范围内运行。如果强度低于某个阈值,则表示需要进行维护,例如更换灯泡或调整固化系统反射器。

工艺验证和质量控制

固化过程必须满足医疗器械制造或电子行业的严格标准。辐射计提供客观、可测量的数据,以验证并记录这些流程可确保遵守法规,并最大限度地减少组装产品出现缺陷的可能性。

辐射计测量 UV/LED 固化装置的光强度。

防止过度固化或固化不足

光强度不准确可能导致过度固化,从而导致材料变脆,或固化不足,从而导致粘合不完全。辐射计有助于微调固化时间和强度,从而避免这些代价高昂的错误。

最大限度提高效率并减少停机时间

用户可以通过定期监测光输出并避免意外的设备故障或产品返工来主动解决性能问题。这种监测可延长固化系统的使用寿命并最大限度地提高生产效率。

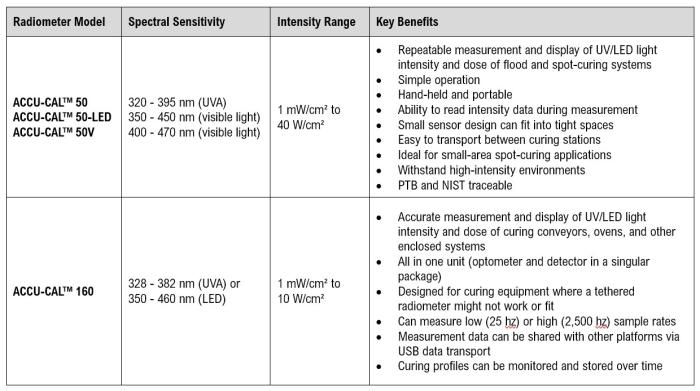

表 1. Dymax 辐射计针对不同光固化应用的比较。

每个辐射计根据光源和固化过程提供独特的优势。ACCU-CAL™ 50 系列辐射计可在高强度泛光和点固化应用中直接监控和测量UV/可见光范围。对于需要准确跟踪和兼容 UV/LED 系统的传送带和烤箱用户,ACCU-CAL™ 160 可提供实时测量功能和数据输出。

Dymax 辐射计提供定量反馈,以确保各个行业的光固化应用获得一致、高质量的结果。