三防漆有哪些种类?

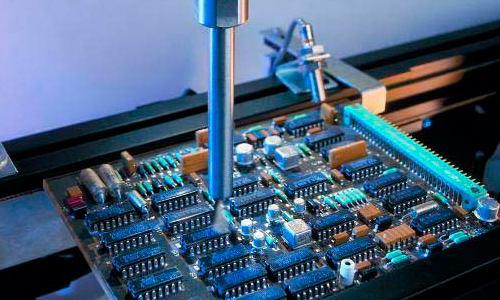

三防漆应用于印刷电路板 (PCB),以保护其免受盐、腐蚀、潮湿和湿气等环境压力的影响,减轻锡晶须,并为元件提供电气绝缘屏障。它们可以设计更小的电气组件,同时增加对元件的机械支撑,并提高焊点的疲劳寿命。

有多种类型的三防漆可供选择,包括硅树脂、丙烯酸树脂、聚氨酯、环氧树脂、聚对二甲苯和光固化化学品。很难知道哪种涂层适合所需的应用,但下面总结了它们的优缺点,以帮助您入门。

丙烯酸三防漆:需要使用溶剂进行涂覆的液体涂料。该产品在印刷电路板上具有出色的防潮性能。在可能接触溶剂蒸汽的应用中,丙烯酸三防漆无法提供最佳保护。它们的耐化学性较差,因此很容易移除并重新加工。

环氧基三防漆:通常,这些材料是双组分系统,使用寿命有限。与聚氨酯一样,它们具有良好的防潮和耐化学性。一个主要缺点是它们几乎不可能通过化学方法去除以便返工。

聚对二甲苯:采用真空镀膜工艺在极高温度下涂覆的涂层。因此,与其他技术相比,它们的成本要高得多。获取有关聚对二甲苯三防漆服务。

聚氨酯三防漆:这些涂料有单组分、双组分、UV固化和水性体系。尽管聚氨酯具有良好的耐化学性和防潮性,但它们通常难以返工,并且在潮湿环境中的耐受性较低。

硅 | 硅胶三防漆:这些涂层通常用于极高或极低的温度环境,具有高防潮和防腐蚀性能以及良好的耐热性,但需要热固化,使用寿命短。硅 | 硅胶涂层也容易磨损(粘结强度低),热膨胀系数高。

氨基甲酸乙酯三防漆:这些材料比其他类型的涂层更耐用、更坚硬。它们被广泛用于印刷电路板,因为它们能提供出色的防化学品和防潮保护。尽管聚氨酯对溶剂具有很高的耐受性,但可以去除涂层进行返工。这些涂层的固化时间通常比丙烯酸氨基甲酸乙酯涂层长得多。

丙烯酸氨基甲酸乙酯(光固化)三防漆:这些涂料是单组分涂料,在暴露于UV/可见光时可快速固化。它们具有良好的耐化学性和耐湿性。许多配方都具有二次固化机制,例如在光线无法到达的区域采用热量或水分固化。除了单组分配方外, Dymax光固化三防漆为用户提供额外福利。

卓越保护

* 符合N/A、Mil-I-46058C 和 UL 标准

* 部分配方具有低释气E595 和 MIL-STD 883 方法 5011 认证

* 优异的耐环境性

* 优异的电气性能

* 对柔性电路(FPC)具有强粘性

* 热循环下应力低

* 非塌陷粘度

* 优异的耐磨性

* 黑色涂层有助于隐藏专有电路

* 优异的耐化学性

卓越的处理能力

* 更容易实现自动化

* 数秒内完全固化

* 无需使用架子或长烤箱

* 无硅 | 硅胶迁移的风险

* 不添加溶剂

* 一次涂抹即可获得厚涂层

* 可修复

* 单组分——无混合或粘度问题

还在寻找合适的三防漆吗?阅读此博客文章 10 个问题在选择一个之前。