三防漆有哪些优势?

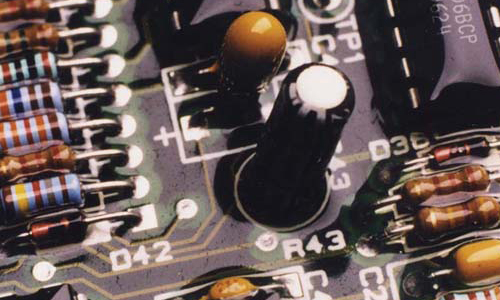

对于从事电子产品印刷电路板生产的制造商来说,确保 PCB 不会发生故障是其成功的关键。因此,他们寻求三防漆等材料,以帮助防止电路板故障并保护组件免受极端环境条件的影响。保护是使用三防漆使用它们的一些主要好处包括:

* 消除腐蚀和拱起

* 增加元器件的机械支撑,提高焊点的疲劳寿命

* 压缩绝缘导电元件的电路占用空间,从而允许元件之间有更紧密的间距。

* 显著减缓锡须的生长

* 由于取消了外壳和封罩,因此重量更轻,组件更小

* 最大限度地减少压力并消除PCB组件的性能问题

需要更多详细信息?下载综合指南光固化三防漆。

三防漆用于哪些地方?

许多人拥有或使用手机、电脑或汽车,它们利用先进的电子技术来运行。许多产品的设计中都集成了 PCB,这些产品暴露在高温、潮湿、使用或具有挑战性的环境中,需要完全保护。

三防漆有助于屏蔽印刷电路板上的电子电路和元件。保形涂层的一些常见应用包括:

* 汽车传感器

* 电池管理系统

* 芯片包封胶

* 控制模块

* 电动汽车充电站电路

* 薄膜涂层/流涂层分配

* 医疗微电路和电子器件

* 卫星、导弹、航天器

* PCB 上的防篡改涂层可隐藏元件

* 引线键粘接

我们的选择指南提供了有关光固化三防漆的详细信息。