双固化三防漆

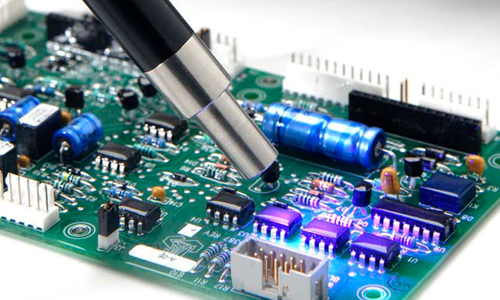

三防漆可提高电子部件的长期可靠性。当涂在印刷电路板的电路上时,它们可起到保护作用,防止破坏性环境条件,如果不涂上涂层,可能会导致电子系统彻底失效。高密度 PCB 和板上的高调组件会产生阴影区域,并且很难完全固化流入这些难以触及区域的涂层。

光固化(丙烯酸酯氨基甲酸乙酯) 三防漆,传统上,阴影区域通过选择性涂层(无需在阴影区域固化)或二次热固化工艺进行处理。双光固化/湿固化三防漆的配方是先在光照下固化,然后随着时间的推移通过二次湿气固化。这种二次固化方法可确保材料完全固化,无需第二个工艺步骤,并且消除了使用热固化时因暴露于温度而导致组件寿命缩短的担忧。

三防漆包括光固化(丙烯酸氨基甲酸乙酯)和硅 | 硅胶、聚对二甲苯和环氧基材料。这些配方固化和加工时间较慢,而且许多配方都已溶解,因此制造商需要考虑安全处理剩余材料,许多制造商正在寻找“绿色”替代品。

戴玛斯双重光固化光/湿气固化三防漆符合 RoHS 规定,不添加溶剂,在广谱或 LED 光照射下数秒内即可固化。快速“按需”固化后表干好使涂层部件可以立即加工。涂层 PCB 可以在光固化后立即进入下一个制造步骤,而不会在湿气固化过程中耽误生产。这些材料还符合重要的测试标准,包括 UL 94 V-0 可燃性和 MIL-I-46058C。

这些特性使 Dymax 双固化涂料成为有意使用更环保产品、提高产量、减少在制品、实现更高制造效率和节省成本的用户的理想选择。

想要了解更多信息?技术公告说明了 Dymax三防漆在 7 天内的湿气固化过程。选择公告:双光固化/湿气固化三防漆在资源区中解锁文档的完整详细信息。