了解光固化材料的保质期

保质期是指商品可以储存而不会变得不适合使用、消费或销售的时间长度。那么保质期是如何确定的,哪些因素会影响它?在这篇博文中,我们将解答有关保质期的 5 个最常见问题,以帮助避免任何代价高昂的错误。

产品的保质期是如何确定的?

产品的保质期由内部产品测试决定。决定不仅取决于化学性质本身,还取决于材料所处的包装尺寸。材料在 15 升桶中储存时的反应可能与在 3 毫升注射器中储存时的反应不同。

在哪里可以找到产品的保质期?

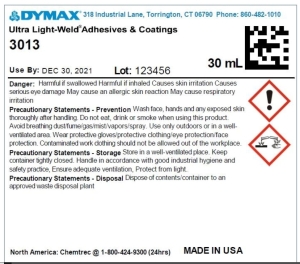

产品的保质期几乎总是列在产品数据表上。每件产品都有一个“使用期限”,即保质期结束的日期。它通常也出现在产品标签上。同一产品的不同包装尺寸可能有不同的保质期 - 所以一定要检查。下图显示了一个带有“使用期限”的 Dymax 胶粘标签的示例。

超过保质期的材料会怎么样?

如果材料在原包装中未使用,且已在建议的条件下储存,则可能会在规定的保质期之后开始产生负面影响。这种影响可能是即时的,也可能是性能缓慢下降的一部分。影响可能包括以下部分或全部:固化时间更长、无法固化、包装中胶凝、粘度变化、脱水收缩/分离以及性能下降。请务必联系您的制造商以回答您可能遇到的任何问题。

储存条件会影响保质期吗?

当然。例如,温度是一个非常重要的因素,您需要注意。如果产品的储存温度高于理想温度,其稳定性和功效就会受到威胁。同样,如果您的储存条件比制造商指示的低,那么潜在的冻结/解冻将导致材料分离,产品质量可能会受到质疑。

材料过了有效期还能使用吗?

是也不是。如果用户希望在保质期过后继续使用产品,大多数制造商强烈建议用户在材料首次投入使用时重复相同的验证测试。例如,光固化材料的测试通常包括固化速率、固化深度和破坏性测试以监测粘合强度。材料用户有责任确定应执行哪些测试标准,以及结果是否仍然符合产品设计要求。