当选择一个 UV面光源固化系统,可以相对容易地比较不同系统的宣传固化区域和峰值强度,并假设值越高意味着光传输量越大。但是,用户多久会考虑一次系统发射光的均匀性?均匀性是衡量整个待固化区域的发射光强度与峰值强度的接近程度的指标,不同的固化设备之间的均匀性可能存在很大差异。

固化UV胶粘剂时,成功固化的最重要因素往往是总光剂量。总剂量定义为照射时间乘以强度。选择泛光固化系统时,用户通常会寻找能够在一定时间内实现完全固化的强度水平。时间和强度的组合由几个因素决定,包括胶粘剂实现完全固化所需的条件以及固化步骤成为瓶颈之前工艺中的可用时间。

最简单的方法是,用户可以通过查看宣传的峰值强度和固化面积来比较两种泛光固化系统,以推断在规定时间内提供的总辐照度。据此,用户可以推断其流程将提供适当的剂量。然而,均匀度的差异会影响提供的剂量,并改变该泛光固化系统的最佳设置。

在许多应用中,例如医疗器械粘接,固化部件在现场不能出现故障。由于最终产品的关键最终用途应用,例如疫苗接种和内窥镜检查,部件必须安全可靠地工作。因此,部件要经过广泛的测试,以确保质量和可靠性。

虽然可靠性至关重要,但在设置固化工艺时,时间往往是重要的次要考虑因素。创建和执行这些工艺的工程师和操作员必须仔细考虑其系统的设计,以平衡正确固化的确定性,同时安排固化步骤,使固化步骤不会减慢其余操作的速度。

优化固化

大多数制造商都会宣传特定泛光固化设备的固化区域和峰值强度。然而,峰值强度通常只在固化区域中心的一个小圆圈内传递。强度通常会在固化区域的边缘显著下降,在角落处下降得更明显。这种差异只会随着与灯的距离增加而增加。

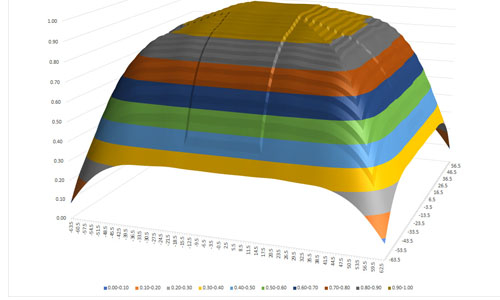

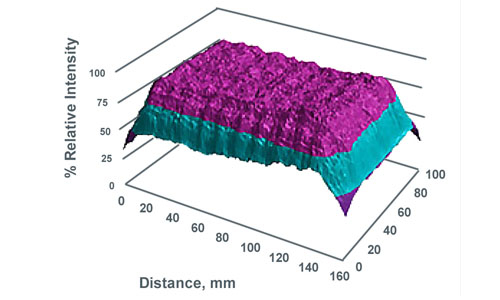

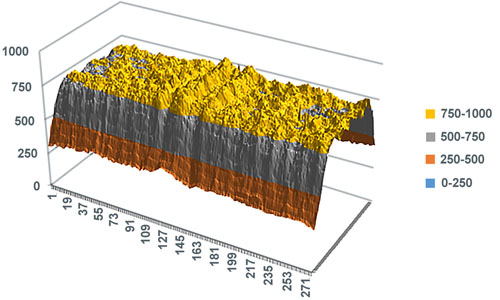

图 1 和图 2 显示了两种不同的 LED 泛光固化发射器的均匀度分布。这两种发射器具有相同的固化面积和额定强度。仅查看数据表上的线条,人们可能会得出它们的性能相同。

图 1. 5 x 5 英寸 LED 泛光发射器 1.

虽然两者中心的峰值强度相似,但 LED 泛光发射器 1 的强度下降到峰值的 50% 以下。 LED 泛光发射器 2 的下降幅度不到 10%(见图 2)。这种差异可能会对用户的流程产生一些影响。

图 2. 5 x 5 英寸 LED 泛光发射器 2.

假设印刷电路板上有多个区域涂有光固化涂层。这块假想的电路板几乎与泛光灯的固化区域一样大,并且整个宽度上都涂有涂层。在这种情况下,LED 泛光灯发射器 1 将向 PC 板边缘的涂层传输不到其宣传峰值强度的一半。

如前所述,总剂量等于照射时间乘以强度。为了达到正确的总剂量,LED 泛光发射器 1 必须将其照射到电路板的时间增加一倍,以达到广告中峰值强度所暗示的剂量。

另一方面,LED 泛光发射器 2 的强度仅在边缘处略有下降,因此只需稍微增加曝光时间即可。此外,板中心的区域将获得明显更高的剂量。虽然光固化材料过度固化的风险往往远低于固化不足的风险,但仍有可能为基板增加过多的热量和固化时间。

此外,具有更均匀均匀分布的泛光固化系统可以更好地优化其使用。为了实现边缘的完全固化,LED 泛光发射器 1 必须更接近其最大输出才能使边缘获得最小辐照度。LED 泛光发射器 2 允许用户选择在较低的设置下运行泛光固化系统,这会对硬件施加较小的压力。在 LED 系统中,它可以将 LED 的使用寿命大大延长到通常宣传的使用寿命之外。

或者,用户可以增加强度以减少固化时间。这加快了固化过程,提高了产量。将固化时间缩短一半可以使装配线的产量翻倍,从而可以更快地制造成品部件,而不会降低质量或可靠性。

均匀性更好的固化系统还可以减少建立工艺和维持工艺控制所需的工作量。在任何工艺中,使用辐射计验证传输的强度都非常重要。如果用户根据均匀性较差的泛光中心的峰值强度来制定工艺,则必须更频繁地测量强度,并测量整个固化区域周围更多点的强度,以确认为固化工艺传输了足够的强度。

均匀性差还会降低固化系统所能提供的效果与实现完全固化所需的效果之间的安全系数。由于光源的强度输出会随着使用而降低,这可能会危及工艺。用户将需要更频繁地进行工艺调整或尽早安装新设备。均匀性更好的系统可以减少测量点的数量,从而减少用于工艺控制的工作量,提供更大的抗衰减余量,并延长设备的使用寿命。

多种固化装置

考虑一下光固化传送带带有多个并排的泛光灯。在这种情况下,吞吐速度通常是最关键的因素,其次是流程的可靠性。

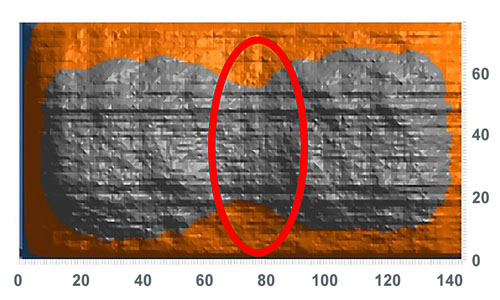

图 3 和图 4 说明了当多个固化设备(例如两个泛光灯)一起使用时,均匀性的影响是如何放大的。安装在传送带上后,LED 泛光发射器 1 在其固化区域的中心提供稳定的峰值强度,但两个发射器之间有一个明显的低谷,强度较低。从中心的峰值强度下降了近 25%,降幅很大。

图 3. 双发射器并排布置的 LED 泛光灯 1 的均匀度分布。圆圈区域表示布置中心的强度降低。

同时,用户通常会设计固化过程,要么将部件置于传送带的中心,要么充分利用传送带的整个宽度。不幸的是,这意味着部件可能只能在固化区域中心外的两个带状区域接受全剂量的固化。

如前所述,用户现在必须以更高的强度运行其洪水固化系统,以确保中心部分获得适当的剂量,同时增加设备的压力。或者,他们可以降低传送速度以增加暴露时间。这种方法可以确保获得正确的剂量,尽管代价是增加循环时间。

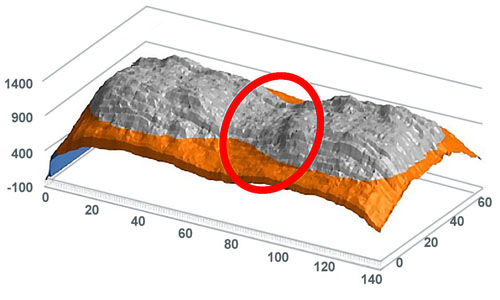

图 4. LED 泛光灯 2 在并排布置中的均匀度分布。出色的均匀度确保边缘区域不会出现下降。

另一方面,LED 泛光发射器 2 的均匀性要好得多,并且并排布置的中间没有凹槽(见图 4)。因此,用户可以通过使用较低的强度设置或提高传送带速度来优化流程。用户现在可以从增加的产品吞吐量或设备的长期可行性中受益。

长期经济效益

通过考虑光传输的均匀性,工程师、操作员以及最终用户可以在整个固化过程中获得优势。这可以减少因质量差而产生的废品,从而节省成本,或通过更快地交付更多产品来增加收入。虽然从泛光固化设备数据表上的简单规格中并不总是很容易看出这一点,但用户应该考虑传输到他们试图固化的部件的所有区域的剂量,并研究他们所选设备的概况。

正如《胶粘剂与密封剂行业》杂志 2021 年 9 月数字版所发表的那样。