利用光固化技术推动电动汽车电子产品发展

预计未来五年全球汽车电子市场复合年增长率将达到 6-7% 左右,其中电气化和高级驾驶辅助系统 (ADAS) 细分市场将激增至 16%。这种前所未有的增长,加上环境法规和安全要求的不断提高,以及消费者对增强车载便利性的渴望,促使汽车制造商寻求在降低总体成本的同时提高系统性能的方法。传统的溶剂型材料和机械紧固件可能购买和使用成本较低,但从长远来看,会增加总体制造成本。因此,许多 EV、BEV 和 PHEV 的设计工程师都转向光固化技术来解决与低吞吐量、废物处理困难和现场故障相关的问题。

“立法变化、消费者需求(尤其是与便利性和/或舒适性相关的需求)以及安全性增强,推动着汽车年复一年的发展。如今,随着电气化和自动驾驶的日益普及,即使汽车需求有所放缓,汽车中电子设备的数量也在快速增长。这些驱动因素,加上对清洁排放和提高燃油经济性的需求增加,也增加了对环保材料的需求,”Dymax汽车电子高级经理 Chris Morrissey 说道。

推动光固化技术在电动汽车电子产品设计中应用增加的三个细分市场是ADAS、信息娱乐和电池管理系统 (BMS)。需要能够解决摄像头模块、激光雷达、印刷电路板和电动汽车电池中传感器、模块和电路常见问题的材料。此外,替换含有危险成分、产生废物且需要更多能量来处理的技术也变得越来越重要。人们还希望增加功能、减小电路尺寸并延长保修期。

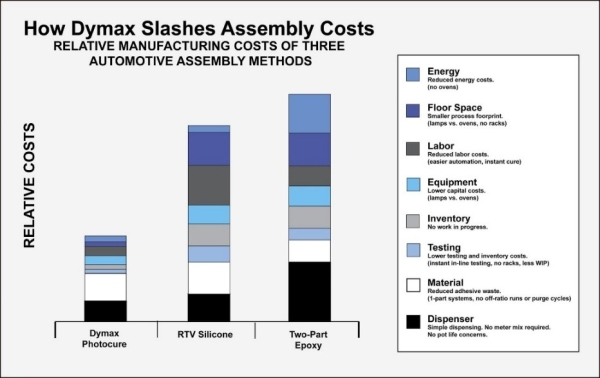

40 年前,Dymax 在如今我们熟知的光固化材料 (LCM ) 的开发中发挥了重要作用。凭借公司创始人 Andrew G. Bachmann 的独创性和前瞻性思维,一种环保且可显著提高工业制造流程生产率的化学品应运而生。与传统的粘接(或连接)技术相比, LCM具有显著优势,包括因劳动力需求减少而降低的运营成本、节省空间、降低能源需求和提高产量。

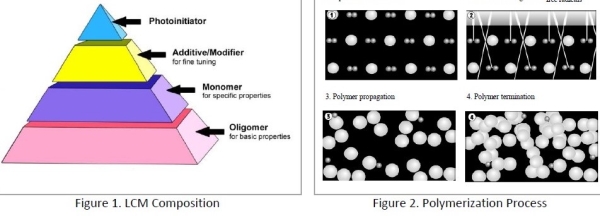

光固化材料如何发挥作用?

光固化材料通常由五种基本元素组成:光引发剂、添加剂、改性剂、单体和低聚物(图 1)。当 LCM 中的光引发剂暴露于具有适当光谱输出的光能源时,紫外线 (UV)光固化过程就开始了。如图 2 所示,LCM 的分子分裂成自由基(引发),然后开始与单体、低聚物和其他成分形成聚合物链(传播),直到所有成分都形成固体聚合物(终止)。在充分暴露于光线后,液体 LCM 会在几秒钟内聚合或固化。

在整个电动汽车电子市场中成功使用的光固化材料类型包括结构胶、三防漆、封装剂和树脂掩膜。自问世以来,Dymax LCM一直致力于最大限度地减少对环境的影响。配方产品均为单组分、无溶剂、不含卤素、符合 RoHS 规定、环保且符合 REACH(无高度关注物质 (SVHC))要求。使用这些产品可为制造商带来诸多好处:

• 改善结构性联系

• 保护电路免受环境损害

• 最大限度地减少移动和收缩

• 解决热管理、热冲击和振动问题

• 增强 PWB/PCA 的功能和性能

• 消除阴影区域问题

• 解决治愈确认问题

粘合剂

光固化胶粘剂在暴露于UV/可见光后数秒内即可固化。它们可与汽车电子制造中使用的塑料、金属和玻璃基板形成高强度、耐环境的粘合。由于它们能够粘合各种基板,因此它们擅长组装不同的材料,这是传统紧固方法和其他化学方法无法做到的。粘合剂的快速固化是LCM相对于其他缓慢固化和劳动密集型应用工艺的一大优势。

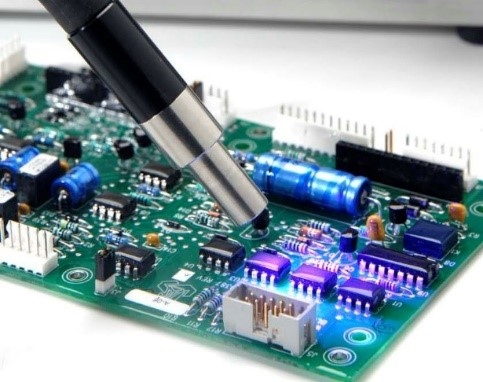

三防漆

三防漆可提高汽车电子部件的长期可靠性。当应用于印刷电路板上的电路时,它们可防止破坏性环境条件,如果不涂层(未受保护),可能会导致电子系统彻底失效。光固化三防漆的一个关键优势是能够使用非溶剂化的“绿色”(100% 固体)材料。其他重要的材料特性包括耐快速和极端温度变化,以及耐高温、潮湿、水分、汽油等化学物质以及盐和硫等腐蚀性物质。

封装材料

用于 PCB 上的裸片、引线接合或集成电路 (IC) 的封装和引线粘接材料具有出色的抗热冲击、高温、潮湿和各种腐蚀性元素性能。它们的快速固化有助于降低替代技术相关的加工和能源成本。

树脂掩膜

临时的可剥离电子掩膜用于印刷电路板组件,以在三防漆应用或波峰焊和回流工艺之前保护它们。极快的固化速度使电路板可以立即加工,无需装架或等待。该产品符合复杂的设计,在垂直和水平表面上不会下垂,与金和铜连接器针脚兼容,并且耐溶剂型三防漆和底漆。经过适当固化后,去除保护掩膜时不会留下任何硅 | 硅胶、离子污染物或腐蚀性残留物。

采用 Dymax LCM 的电动汽车电子应用

各种 Dymax LCM 化学成分中融入了多种技术,以改善电动汽车电子产品的整体制造。

阴影区域固化

双重光固化/湿气固化技术

双固化涂料的配方可确保在高密度电路板上存在阴影区域的应用中完全固化。以前,遮挡光线的区域通过选择性涂层(无需在阴影区域固化)或二次热固化工艺进行管理。阴影区域会随着时间推移在水分中固化,无需进行第二个工艺步骤,也无需担心由于暴露在高温下导致组件寿命缩短。

多重治愈®光/热固化技术

多重固化粘合剂和涂层将紫外线或UV/可见光的高速固化与增强聚合的二次固化机制相结合。当光线只能到达粘合线的一部分时,或在最终固化之前固定部件以在制造过程中更轻松地处理和运输时,二次固化机制(包括湿气、热或活化剂固化)非常有用。

增强粘合线检测

蓝色荧光技术

许多光固化材料都采用了可轻松进行目视固化确认和固化后检查的技术。在高速制造中,自动化视觉系统用于检查成品部件的粘合线缺陷或检测不完整的涂层覆盖。采用蓝色荧光技术的配方在低强度黑光下可见,可轻松目视确认成品部件是否正确完成。

色彩鲜艳的材料

一些LCM在未固化状态下含有粉色或蓝色等彩色颜料,当它们被分配到基材上时,可以很容易地被看到,以确保材料完全覆盖。一旦暴露在适当数量的 LED/ UV/可见光能量下,颜色就会转变为另一种颜色或变成无色,从而确认完全固化。

利用环境加速生产环保固化

LED光固化技术

由于处理危险废物的成本和难度,制造商开始在其工艺中采用 LED 固化材料和光固化。LED 固化被认为是一种“绿色”技术,因为它为制造商提供了以下好处:

• 高电气效率和即时开/关能力,降低运营成本

• 使用寿命长,无需更换灯泡,降低维护成本

• 紧凑型设备,减小了光固化系统的尺寸和成本

• 冷光辐射可延长热敏基材的固化能力

• “绿色”属性消除了汞和臭氧安全风险及处理成本

• 窄波长光谱发射可最大程度地减少基底温升

ADAS - 主动对准 (CMOS) 和激光雷达(粘合剂、封装剂)

Dymax 粘合剂和密封剂可用于各种摄像头模块和激光雷达应用,包括摄像头模块固定、镜头到外壳、镜头固定、红外滤光片粘接、外壳到基板、芯片粘接、挡风玻璃粘接以及图像传感器到基板。ADASADAS头模块制造的关键是镜头在摄像头模块外壳内的定位和固定。该行业正在逐渐摆脱被动对准(即使用夹子的机械固定),因为被动对准会导致镜头移位、倾斜、散焦和旋转。使用光固化胶粘剂的主动对准可以快速固定(以秒为单位),实现高精度(< 0.1 毫米)和光学控制多轴对准。此外,由于聚合直到暴露在光能下才会发生,因此组装的部件可以移动直到正确定位。定位后,密封剂用于保护组件的环境保护。Dymax CMOS 粘合剂还具有以下特点:

• 冷船/冷储以及常温储藏

• 低收缩

• LED 和/或热固化能力

• 耐湿气和热循环

这些材料为组装过程带来的其他一些好处包括氨基甲酸乙酯丙烯酸酯和阳离子紫外线和/或热固化技术、LED 固化配方、极低的移动性、耐热、耐湿性(85°C,85% 相对湿度)以及与金属和塑料的优异粘合性。

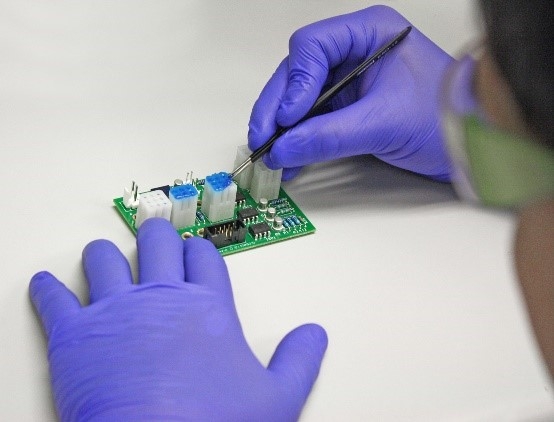

信息娱乐(基于PCB )(三防漆、封装剂、掩膜)

对于希望在其PCB设计中采用光固化技术的工程师来说,一个关键考虑因素是电路板是否具有高轮廓元件,这些元件会在光线无法到达的阴影区域。新配制的 100% 固体三防漆具有二次湿气固化功能,可使阴影区域下的材料固化,有助于消除对PCB上未固化材料的担忧。这些产品在耐热耐湿(85°C,85% 相对湿度)、耐热冲击(-55°C 至 +125°C)和耐腐蚀(硫花、盐雾和常见的汽车液体)等测试中表现出色。Dymax 双固化三防漆允许设计更小、更密集的 PCB,因为它允许导体之间更短的空间,增加对元件的机械支撑,并延长焊点的疲劳寿命。

封装材料是用于保护芯片和互连的聚合物材料,可确保板上芯片 (COB) 组装的长期可靠性。Dymax 材料用于液体和圆顶封装封装应用,在这些应用中,它们被分配到芯片及其线路的顶部,然后固化以形成保护屏障。

光固化掩膜是一种临时材料,用于在表面处理和组装过程中保护印刷电路板。

电动汽车电池组/BMS(三防漆、封装材料、粘合剂)

电动汽车电池组包括一个电池管理系统 (BMS),用于监测充电状态、温度、电流、平衡电池、确定允许的操作条件并向驾驶员发送信息。常见的电动汽车电池应用包括电池模块的灌封和引线粘接、BMS 中 PCB 的涂层保护、电池外壳的密封和单元电池中电极的包封胶。一系列LCM用于粘合和保护这些组件,包括用于热管理和外部保护的三防漆、用于…的结构胶以及用于引线粘接的封装剂。Dymax 材料最有效地用于圆柱形锂离子电池单元的粘接和固定,这些单元必须固定在塑料外壳单元和 PCB涂层内。

随着电动汽车电子市场的发展,Dymax 将继续开发光固化技术,使制造商更有能力、更高效。