本案例研究介绍了光固化胶粘剂如何取代双组分环氧树脂,以加快传感器组装速度并改进应用流程。 ...

红外荧光技术可立即进行质量检查

关于如何使用专利的 Ultra-Red® 荧光技术帮助进行产品验证的案例研究。

挑战

了解快速诊断医疗设备为何失败

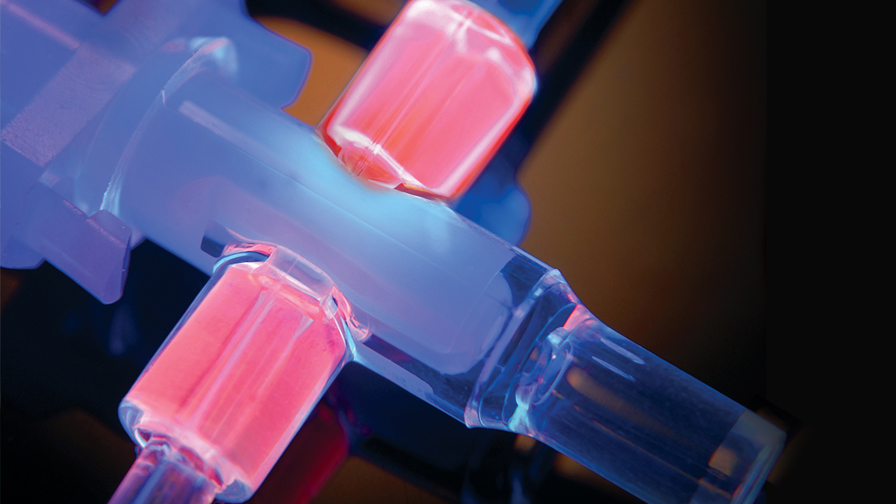

一家快速诊断医疗设备制造商面临着现场故障和高达 30% 的废品率问题。此外,还存在粘合问题和墨盒泄漏问题。该应用涉及将陶瓷盘粘接到塑料孔中。客户怀疑用于组装零件的粘合剂不起作用或材料不对,因为组件无法正确粘合在一起。快速确定粘合剂是否适合该应用至关重要,解决问题至关重要,因为出现更多现场故障的可能性很大,客户只能等待问题被确定。

解决方案

利用 Dymax 专利的 Ultra-Red® 荧光技术进行视觉产品确认

制造商联系了 Dymax,希望该公司能帮助解决这一问题。一些发生故障的部件被送往实验室进行检查和根本原因分析。经过仔细检查,应用工程很快确定粘合失败是由于使用了错误的粘合剂。该应用指定的产品是 Dymax 1172-M-UR ,采用专利 Ultra-Red 荧光技术配制的粘合剂。在低强度黑光下,部件上暴露的粘合线发出蓝色荧光,而不是红色荧光,这表明部件上涂的是其他公司的粘合剂,而不是 1172-M-UR。

结果

相关产品

查看与该产品配合使用的其他 Dymax 产品,以创建完整的解决方案

查看与该产品配合使用的其他 Dymax 产品,以创建完整的解决方案

粘合剂取代双组分环氧树脂,实现更快的光学传感器组装

航空航天改进PCB三防漆工艺

通过提高产量来改进PCB三防漆工艺的案例研究。 ...

航空航天改进PCB掩膜工艺

关于改进航空航天和国防制造商的PCB掩膜工艺的案例研究。 ...

航空航天掩膜镍掩蔽工艺

掩膜镀镍掩蔽工艺案例研究 ...

航空航天印刷电路板组装

提高PCB组装产量并减少加工时间 ...

自动掩膜系统彻底改变了表面处理工艺

有关自动掩膜线如何大幅减少航空发动机部件所需处理时间的案例研究。 ...

汽车前灯中的 MLA粘接

用于粘接汽车前灯 MLA 的粘合剂在高温下不易变色 ...

Cinch 游戏控制器增强了握感

Cinch Gaming 是定制专业视频游戏控制器领域的全国领导者,该公司正在寻找一种耐用的解决方案,为其 ABS 塑料控制器外壳提供橡胶握把涂层。 ...

电气防爆与传感器技术

电气防爆和传感器技术领域的一家全球领先企业正在考虑放弃激光焊接,转而采用需要密封其光电传感器的两个聚碳酸酯的应用。 ...

GenZe 电动交通工具电池组垫片

使用现场成型密封垫圈来创建可靠的电池组件,满足重量、性能和安全性的严格设计标准。 ...

电动汽车充电站的高性能解决方案

关于光固化三防漆和封装材料如何帮助改善电动汽车智能充电站基础设施PCB应用的案例研究。 ...

光固化传送带可实现 100% 制造规模扩大

案例研究:如何使用 Dymax UVCS光固化传送系统来帮助提高鼻拭子产量。视频哦: Dymax 与 3D 打印机公司合作开发 COVID-19 测试拭子#同舟共济 ...

单组分光学环氧胶,采用UV/可见光固化

使用紫外线和热固化将相机模块支架固定至PCB 的案例研究。 ...

加固手电筒中的透镜和反射器外壳

一家领先的高级便携式照明制造商希望增强消防员、警察和军队在野外使用的安全手电筒的耐用性。在寻找具有出色粘合性能的快速固化密封剂时,他们向 Dymax 寻求帮助。 ...

UV胶粘剂可防止热电偶抬起,从而实现可靠的回流焊曲线分析。

案例研究探讨了在严苛的回流焊环境下,粘合剂粘接如何优于胶带和焊料粘接。随着印刷电路板 (PCB) 设计变得越来越密集和复杂,实现精确的回流焊温度控制变得前所未有的重要。焊接过程中的温度偏差会导致冷焊点、翘曲或元件失效等问题。为了确保稳定的热性能, 罗切斯特理工学院(RIT)与……合作KIC热能公司评估了几种热电偶 (TC) 连接方法对无铅回流焊过程中测量可靠性的影响。通过广泛的多周期测试,RIT...