What is the difference between an LED bulb and a broad-spectrum mercury-arc bulb?

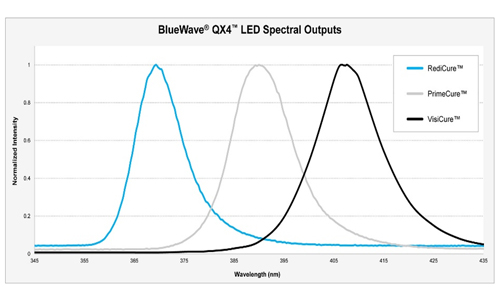

LEDs (Light-Emitting Diodes) are semiconductor light sources that emit very discrete wavelengths of light energy, resulting in a single, narrow, bell-shaped emission spectrum, as shown in Figure 1. Conventional mercury-arc bulbs are considered broadband light sources because they emit light over a wide range of wavelengths including short wave UV, long wave visible, and even longer wave infrared.

Will bond performance be similar whether you are using an LED or a conventional lamp light source?

The direct replacement of an arc lamp spot-curing system with a LED spot-curing system - without evaluation and process adjustment - can result in substandard bond performance. Differences in LED wavelength distribution and intensity necessitates the evaluation (if not formulary modification) of the chemistry and curing-energy dosage. There are some adhesives that provide the flexibility to use both types of light sources without changes to your process. Verification is strongly recommended to ensure successful results.

Do LED adhesives cure best at the 365 nm wavelength peak?

Traditional mercury arc lamps indeed emit a high level of energy at the wavelength peak of 365 nm. However, this does not mean that an LED light source with a 365 nm peak will provide the best performance. The reality is that many light-curable chemistries, including acrylated adhesives, use photo initiators that respond best to the narrow, bell-shaped spectral curve.

What should be considered when selecting an LED light source?

Substrate(s), adhesive, dispense methodology, and curing approach should all be considered. To implement LED curing technology into any application, it is important to determine if all the components are optimized with one another. As many manufacturers have experienced, simply inserting LED curing into an already existing process is not a guarantee of success. This assumption of interchangeable parts can result in frustrating performance failures that ultimately cost manufacturers time and money. To yield the required performance characteristics from the adhesive, it is essential to match the wavelength of the LED lamp with the absorption spectrum of the light-curable materials (LCM) photoinitiator in the adhesive. This successful pairing is dependent upon having an optimized solution in which a cohesive combination of compatible LCM and LED curing system is established.

To understand more about changing over to LED curing, visit our Resource Library to obtain a copy of the white paper, “Ensuring Success When Switching from Conventional Lamp to LED Light Curing Sources.”